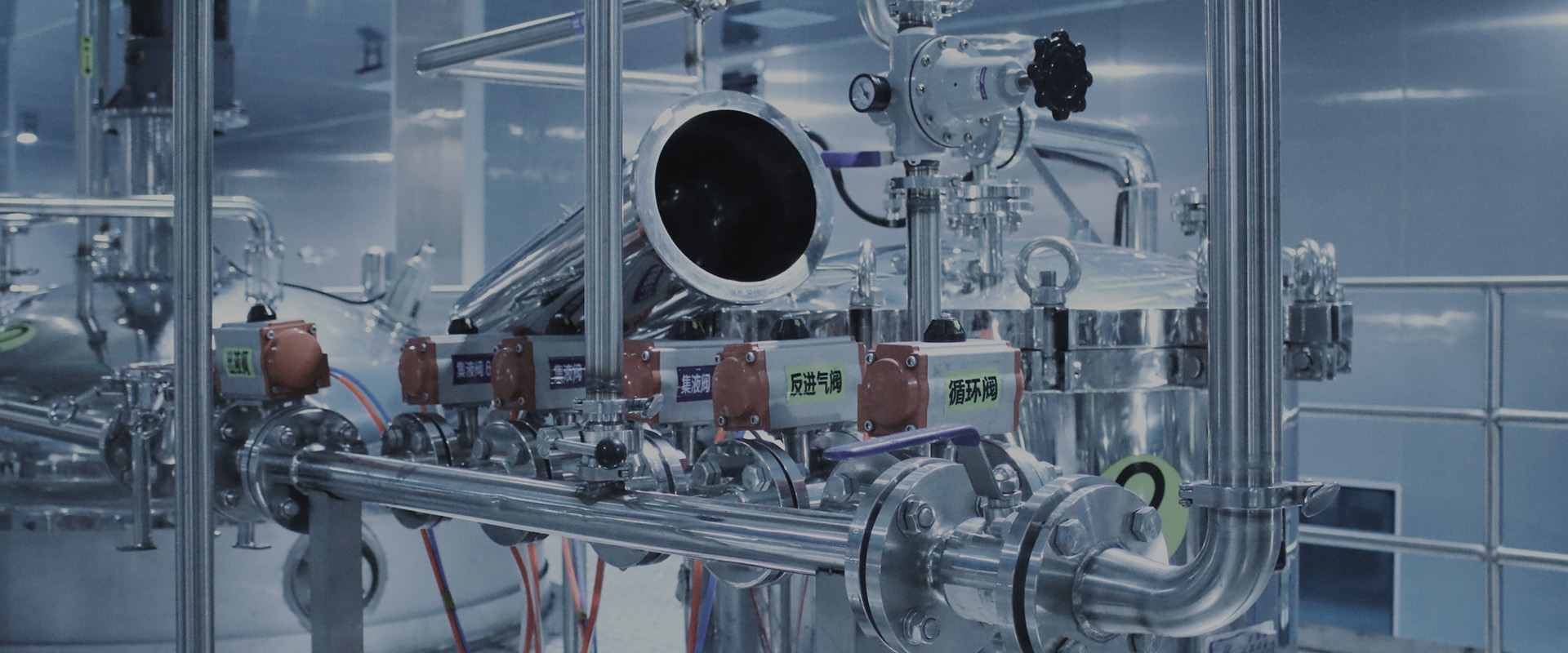

公司拥有系统的低聚肽生产线,建立了海洋生物、植物预处理系统、生物反应系统、脂肪分离系统、蛋白质与肽分级系统、10万级空气净化车间及造粒干燥系统。新引进的GMP生产车间可生产建设多条自动化高科技生产线。生物肽系列产品的分子量在1000道尔顿以下,其中分子量在100-3000道尔顿的阿胶低聚肽适宜人体吸收,保留了原材料的生物活性,确保原材料能够被充分利用。原材料都是精心挑选,生产出产品的质量合格率为100%。

公司配备:

全自动酶解罐(全自动酶解罐具有温度自动控制、搅拌自动控制、温度曲线记录,PH检测、自动清洗、计量添加等功能,酶解罐产品采用PLC触摸屏进行现场控制或远程微电脑控制,实现全自动控制方式)

喷雾干燥设备(喷雾干燥塔干燥速度快,干燥的产品具有良好的均匀度、流动性和溶解性,产品纯度高,质量好。生产过程简化,操作控制方便)

陶瓷膜过滤设备(相比于传统过滤设备,采用陶瓷膜过滤分离技术具有过滤速度快、澄清度高、收率高等优点)

纳滤膜浓缩设备(与传统离心分离、真空浓缩、多效薄膜蒸发、冷冻浓缩等工艺相比,纳滤浓缩的环境温和,降低了美拉德反应,还兼具有脱无机盐和氨基酸的作用,提高原料肽的品质)

卧螺离心机(该机能在全速运转下,连续进料、分离和卸料。具有结构紧凑、连续操作、运转平稳、适应性强、生产能力大、维修方便且能耗低等特点。适合分离含固物粒度大于0.005-10mm,浓度范围为2-40%,温度≤100℃的悬浮液)

全自动灭酶机(本设备采用多组列管式结构,自动物料回流设计。自动控制温度,出口物料温度可调节,能够快速灭酶活酶解过程中添加的酶,防止产品因酶作用产生的沉淀,减少美拉德反应)

还掌握生物酶解的核心技术——辅助蛋白酶解技术 (通过微波、高压、超声波等辅助技术,来提高蛋白酶酶解活力,从而显著提高了原料肽收率,降低生产成本)

复合酶梯度定向酶切技术(利用不同酶酶切位点不同,筛选多种特异性蛋白酶,进行梯度定向酶解,酶切出有功能活性的肽段,实现目标肽靶向释放的制备技术)

定向分离技术(以具有功能活性的肽段为目标肽,采用多种分离技术进行定向分离,从而实现了目标肽的富集,提高了原料肽的功效性)

多肽风味改良技术(利用吸附、萃取、色谱分离等技术分离苦味肽和腥臭味,通过味道掩盖技术、美拉德反应技术来改善不良气味和口感)

同时,公司拥有标准化化验室,对每批产品建立了质量追溯体系,用标准的实验器材和检验方式,确保产品质量,勠力同心的践行着“ 为国人做好肽 让人民更健康”的企业发展目标。

咨询客服

咨询客服